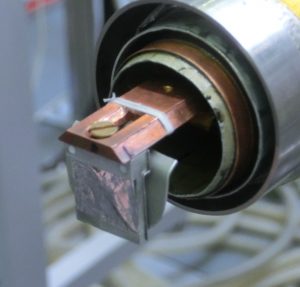

A couple of days ago, the work on one sample ended, and so we switched to a new superconductor. The above photo shows the original sample attached to the cold finger of the cryostat. The sample is the aluminium plate screwed in to the copper cold finger. A piece of cadmium is hanging in front of the sample. Cadmium absorbs neutrons very well, and so is used to mask off areas that might provide unwanted background scattering, and to provide the final slit in the scattering setup, defining the sample. The sample itself (which is a set of thin plates, co-aligned on the aluminium holder) is covered with aluminium foil. Perhaps the main reason for this is to make sure that if the sample works loose, it is caught and doesn’t fall into the cryostat. The samples themselves are stuck down with a very thin glue. We typically use Bostik, well watered down with acetone. The aim is to have as little glue as possible in the beam, as hydrogen atoms scatter neutrons strongly, and so can introduce a lot of background. Other common glues used are GE varnish, STYCAST, and occasionally Cytop, a fluorinated glue. This removes, or reduces, the hydrogen problem, and is fine for small angle neutron scattering, but can be more problematic for more typical diffraction experiments, as there is a strong, broad peak from the glue at higher angles.

And now, with new sample installed, and a signal seen, I am handing over to the other part of the team to continue the experiment.