In its 23rd year, Joy Grey, Education Liaison Officer, and Dr Charles Watson, Teaching Fellow, led a week-long study tour covering Holland, Germany, Austria, and Poland. It’s an opportunity for students to find out more about the world of railways outside of the classroom.

Here, MSc Railway System Engineering and Integration (RSEI) students write about the tour…

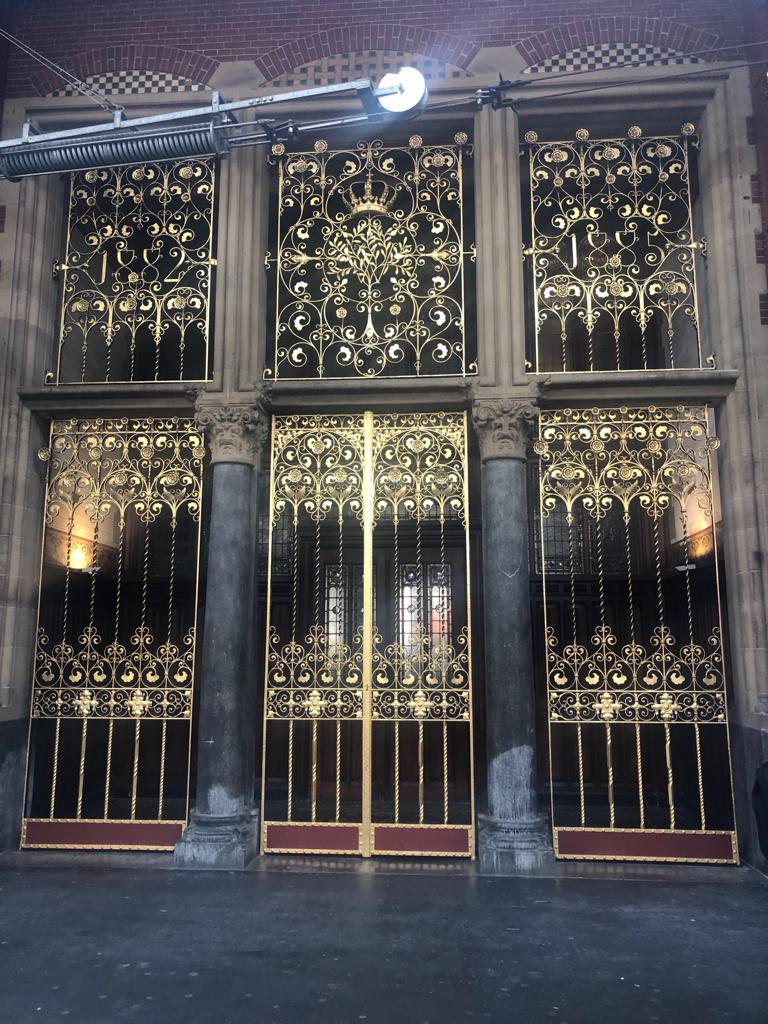

Day one – Amsterdam, Holland

Today we had a behind-the-scenes tour of Amsterdam Centraal station. There is a huge programme of improvement works taking place in the coming years, which will transform the station and surrounding area. Lee also touched on the complexities that such a huge programme brings, such as protection of heritage railways, whilst expanding and modernising the station for future proofing passenger footfalls. Lee Verhoeff, from ProRail, hosted our group – thanks to Lee for a really interesting day!

Day two – Cologne, Germany

Today the RSEI European Study Tour (East) visited HGK Transportation. They manage all rail haulage from the river Rhine to the surrounding areas in Germany, predominantly Cologne, Hamburg and Frankfurt.

Key facts we learnt today:

- Locos being changed over the next 20 years to dual mode diesel electric units; each new unit costs 5.6m euros.

- The yard refuels all its loco’s to the tune of 4.3m litres of fuel a year.

Day three – Vienna, Austria

We started the day in Vienna (not so) fresh from the overnight sleeper. Then onto Wiener Linien depot, Hauptwerkstätte Simmering for the day to learn how they maintain 320 trams and 500 buses which serve Vienna everyday.

We were shown the 250,000m2 site where among other things, they repair, maintain, refurbish and fabric parts for these units. The site also has an education centre, for their annual 50+ apprentices, repair the bus fleet and maintain their own road vehicles on the same site.

The afternoon was spent learning about the infrastructure part of the operation where we saw the construction of switches and crossing sections for intended use on renewing parts of the 237km of track and 687 switches they cover. It was very impressive.

Day four – Linz, Austria

We visited Plasser & Theurer, Linz, Austria. Founded 1953, the company has 1900 employees in Austria, 4000 employees globally and works with 19 partner firms around the world.

It manufactures various types of unit that operate in the following areas:

- measurement

- tamping

- ballast management

- overhead line

- renewing and laying tracks

- material logistics

- stabilisation

- consolidation and ballast cleaning.

Plasser has produced Hybrid and electronic tamping units capable of travelling under their own power. Tampers are now digitally controlled and can recognise sleepers and work automatically. New measuring trains can survey at 100kmh.

Units have GPS and internet connections, meaning measuring units can talk to tamping units, reducing the time taken to conduct maintenance.

During a walk through the assembly shop, we observed units being built for South Korea, Japan, Algeria and Bulgaria. Since 1953, 16000 units have been delivered all over the world.

Day five – Krakow, Poland

As railway engineers we strive to design, build and operate railways for the good of all mankind. Today’s visit to Auschwitz-Birkenau showed us the most sinister use of the mode. We were all deeply moved by the experience.

Day six – Warsaw, Poland

We visited the Warsaw Tramways LTD known natively as Tramwaje Warszawskie in Poland’s capital city.

We learnt about the various challenges experienced by the operator and future plans to extend the tram lines in the City.

Do you know that tram operators are given 20mins allowance to carry out repairs to broken down trams causing disruption anywhere on the network, after which they face a fine!

Warsaw Trams hold approximately 25% of the modal split of public transport within the city. The tram services operate on 303km of infrastructure of which 263km are used for passenger traffic and the rest for other areas such as depots.

Currently, there are ongoing plans to extend the network including the construction of a new depot, Annopol. The operation of trams is made easy by an “intelligent” traffic management system, VisSim, with priority given to trams at traffic lights.

Thanks to Jaroslaw Szustek and Grzegorz Madrjas for hosting our group.