By Stephen Kent, Teaching / Research Fellow at BCRRE.

So how much carbon dioxide is a train responsible from the time it’s manufactured to the time it’s disposed of at the end of its life? And how can the choices that those procuring trains and designing trains affect this? These are two key questions that a recent RSSB study set out to establish

The investigation, undertaken jointly by BCRRE and Pragmatex looked at the ‘cradle-to-grave’ emissions associated with passenger rolling stock, including Scope 1, 2 and 3 emissions (effectively diesel consumption, electricity consumption and the carbon embedded in the train during manufacture and the replacement of key maintenance items during its life).

So to question 1 – what exactly are the carbon emissions associated during a train’s life?

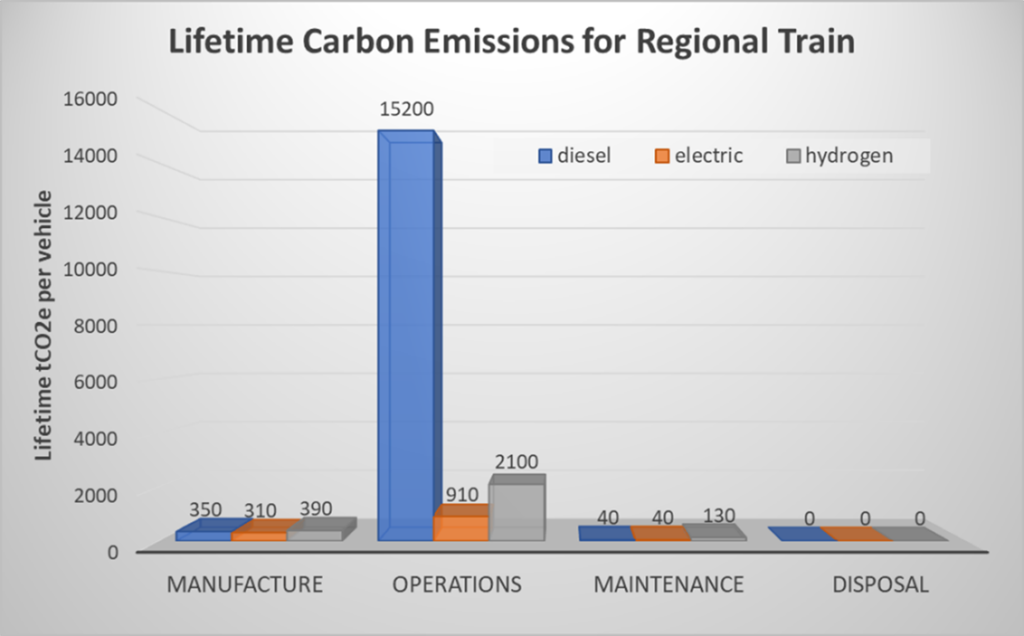

The answer to this is shown in the chart below for a typical regional train:

The train’s life is split into four periods – its manufacture, its operation, the carbon associated with the manufacture of key components involved in its maintenance, and disposing of it at the end of its life (in actual fact, it’s more like recycling, as well over 90% of the train is made of materials such as steel and aluminium that are readily recycled!).

The numbers are presented for an individual vehicle (i.e. a 3-car train would be 3 times these), and they indicate a stark difference between a vehicle that is powered by diesel, electricity from overhead wires or third rail, or hydrogen (produced from grid electricity).

Overall, a diesel vehicle is responsible for the order of 16,000 tCO2e over its life, but an electric vehicle is about 1/12th of this, and a hydrogen powered vehicle around 1/6th of diesel.

On to question 2 – so the answer is to electrify everywhere isn’t it?

It’s not quite that simple – as any industry expert will tell you, electrification is fantastically expensive, and takes considerable time to implement. So while it can be justified for primary routes (i.e. heavily used rail lines), it isn’t realistic or affordable for lesser-used lines. So, what are the alternatives?

Well, as indicated in the chart, hydrogen powered trains offer a substantial benefit, and probably make sense for rural lines that are unlikely to ever be electrified. But there are other approaches, including so called ‘electric bi-modes”. Such trains have a sizeable traction battery (probably equivalent to the largest electric car battery in term of energy storage capacity per vehicle), which enables them to travel 50km or more on battery power. Such trains can bridge gaps in electrification, or extend the effective ‘reach’ of exiting electrification schemes. While it’s true that there is a significant amount of carbon emissions associated with battery manufacture, this pales into insignificance in comparison with the savings in operational carbon emissions (remember that a typical regional train that might do 150,000 miles a year or more).

There are then ‘diesel bi-modes’ which are similar, but have a diesel generator on-board to power the train when operating on non-electrified lines in place of a battery – such trains can run much further under their own power, so are well-suited to longer routes that are only partly electrified. The sort of carbon emission reduction this offers is roughly proportional to the amount of time they spend ‘under the wires’ – e.g. for a 50% electrified route, carbon emissions will be roughly half that of a diesel-only train. And of course, the more of the route that is electrified over time, the smaller become the train’s operational carbon emissions.

And even if it is necessary to order future fleets of diesel-powered trains, there are significant reductions in carbon emissions (and fuel consumption!) that can be made by hybridising the diesel engines – i.e. where a smaller diesel engine works in conjunction with a battery pack to power the train, much in the way that a hybrid car does. Similarly, employing stop-start technology, improving train aerodynamics, and cutting vehicle mass can also contribute to the reduction.

It’s also worth remembering that travelling by train is already a low-carbon form of transport, and with the increasing drive of the industry towards greater electrification, it’s only going to get better.

If you would like further information or have any queries please email: railway@contacts.bham. ac.uk