It’s been a month since my last blog, and in terms of placements, that’s a long time! In this blog I’m going to give you a slight variation on the “Day in the life of…” type blog, the reason being there is no typical day when you work in R&D! In short, I work on existing and new experimental rigs, some of which I’ve built from scratch with the help of my colleagues. I mentioned in my last blog that I can be quite fickle and working in R&D caters to that with the constant moving between traditional researching and doing practical things like experiments and building rigs! So, sit back and (hopefully) enjoy this read on the Day in the life of a Calgavin Placement Student.

It’s been a month since my last blog, and in terms of placements, that’s a long time! In this blog I’m going to give you a slight variation on the “Day in the life of…” type blog, the reason being there is no typical day when you work in R&D! In short, I work on existing and new experimental rigs, some of which I’ve built from scratch with the help of my colleagues. I mentioned in my last blog that I can be quite fickle and working in R&D caters to that with the constant moving between traditional researching and doing practical things like experiments and building rigs! So, sit back and (hopefully) enjoy this read on the Day in the life of a Calgavin Placement Student.

0830:

Calgavin runs on flexitime, meaning I can come in and leave when I please (within reason) as long as I meet the minimum work hours required for that pay period. I like to get in early most days, as I tend to take half days on a Tuesday so I can attend French classes at Uni. I grab a cup of tea before saying hi to my colleagues and then take a look at my to-do list for the day.

0900:

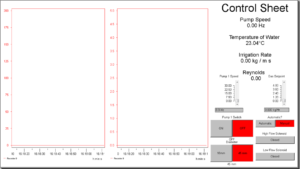

It’s time to get experimenting! Calgavin has many experimental rigs to test the inserts they sell commercially as well as new technologies and insert designs. Almost all are automated, and thus, can be run in the background while I do other things. I start up the rigs I am experimenting on, choose whatever test meets the aims we as a department have discussed beforehand, and let the rig do its thing. Start-up can take between 10 minutes to an hour depending on whether I was testing the day before, I need to switch inserts or tests, or I need to top-up experimental fluids.

0955:

Pop up to reception to grab another cup of tea to take in with me to my first meeting of the day.

1000:

The only regular meeting I have, is our departmental Monday morning meeting. Otherwise, we set up meetings whenever we have new projects, a webinar to watch or if certain experiments need to be discussed or reviewed. Our Monday morning meetings are typically to discuss progress made on projects mentioned in the previous meeting, and to talk over what our goals will be for the coming week.

1045:

I check in on the rig to ensure the experiment is going as planned. I can check my results in real time with spreadsheets made by previous placement students. Even though I do have my own project for the year, I still use documents, workbooks and programmes developed by my predecessors.

Depending on how I’m feeling, I’ll either

- Read a journal article given to me by my boss. These articles can provide valuable information that often helps me when I’m building a rig and thinking about the best way to meet the experiments objectives.

- Put my theory to practice and either plan what a rig will look like, how it will work and how data will be taken, stored and analysed.

When designing experiments, it’s important to think about what you’re measuring and how exactly you’ll do that. Do you need to measure a different variable and manipulate it to recover the information you want? What instruments must be used to get this data? Is what you’re doing necessary, or is there a simpler approach?

1200:

Hitting a stump is inevitable in R&D, so usually after a few hours of work, I’ll talk to my colleagues about what I’ve completed and where I’m having problems. Group work or even a simple conversation with co-workers is such a fundamental part of engineering/science, as it allows you to share ideas and solve problems you would not have been able to solve by yourself.

1230:

LUNCH TIME

1300:

Back to work. I check in on the rig again as sometimes parameters and valves on the rig need to be changed to help the rig reach steady state.

Data storage and analysis is vital, and to ensure I have the tools to do that, Calgavin has access to a series of web courses that teach how to code in VBA, Python, and C+ as well as how to understand Modbus communication. When I don’t have any impending deadlines, I’ll spend an hour or two learning how to code or use new software.

All our rigs are either pilot plant scale or smaller, so buying equipment isn’t always easy. We occasionally have to design our own pipes, fittings, etc. and manufacture them in house. Sometimes drawing things as simple as a distributor can take up to 2 hours! But seeing something you’ve drawn, come to life and get implemented on a rig is totally worth it.

1455:

Tea break (again 😊)

1500:

Most of my experimental results need to be presented to the company or to some of our collaborators (other universities and companies). I love making PowerPoints or taking pictures of my experiments, so I’ll typically try and do my presentations at the end of the day when I’m a bit more tired. I had to do a presentation on my findings to two companies who, in my opinion, were quite impressed.

1630:

It’s almost home time. I shut down the rigs, making sure all the valves are in the correct positions to prevent leaks and make note of where the testing reached, if it didn’t finish.

1700:

Home time!

I hope you enjoyed this glimpse into my day-to-day activities. Come back next month where I will be telling you about how I balance my work like and social life while on a placement!