Reza Zolfaghari, Senior Technical Officer with the Digi-Rail project and an expert in systems engineering, considers asset management processes and systems.

The requirement of modern railway asset management is moving from reactive maintenance, towards smart, proactive and condition-based maintenance which uses data obtained directly from the assets themselves. There is no doubt that technological innovation is essential to achieve this goal, but is technology on its own adequate?

Modern railway asset management is heavily data-driven. Railway assets are diverse in type, material and function; they are dispersed whole around the country and they operate within variable conditions. Railways are complex systems formed of numerous sub-systems, including assets. Having innovative methods for collection, storage, analysis and utilisation of asset data can improve the quality of asset management processes. In turn, improved asset management reduces failures and their associated costs.

Railway sub-systems are interconnected and interdependent and the change or failure of each asset will affect other assets and the functionality of the whole railway system. This interconnectivity and interdependence adds more complexity and increases the risk of asset failures. The combination of asset failures, non-harmonised maintenance regimes or missed data can create catastrophic and unpredictable failures, regardless of whether cutting-edge technologies might be in use.

Metaphorically, considering railway asset management as a human body, technological innovation would be undoubtedly the heart. But a brain (or a systems-thinking approach) is required to integrate, harmonise and systemise the heart’s function with the other components (sub-systems). Work prioritisation is another factor playing a significant role in achieving integrated asset management. As an example, Network Rail owns more than 20,000 miles of track, 30,000 bridges and tunnels, 2500 stations and a vast range of equipment installed. Scattered sets of data need to be collected and analysed and decisions made, to establish a maintenance regime and choice of technology. However, because of the interdependence of assets, there should be a reliable impact analysis method in place to measure the impact of maintenance activities on each asset on the whole network safety, punctuality and reliability. For instance, lack of coordination between track and signalling maintenance team can lead to rework, unexpected delays and disrupted operation.

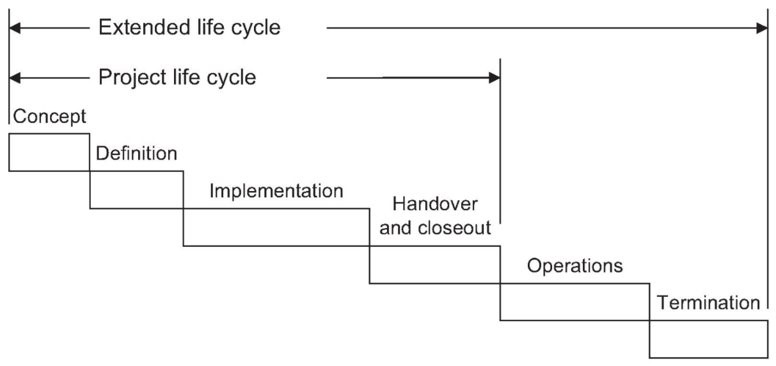

Asset management embraces all systems, procedures and tools to optimise an asset’s availability during its whole life-cycle, whilst reducing whole-life cost and risk. Another key factor to achieve integrated asset management is the use of an holistic-extended-life-cycle based approach and promotion of Safety By Design. This means that potential risks and failures can be foreseen and eliminated in the asset’s design phase to reduce future maintenance costs.

In conclusion, integrated railway asset management is data-technology driven, but to achieve a safe, sustainable, reliable and cost-efficient asset management strategy, an holistic and systems-engineering-based approach allows the following:

- Harmonising maintenance strategies;

- Optimising decision-making;

- Consideration of a whole-life-cycle approach to facilitate safety-by-design and cost reduction, and

- The asset owner can optimise, systematise and coordinate the use of technology, with a focus on maintenance effectiveness.

In BCRRE and its projects, including the Digi-Rail project, we offer a broad range of research activities, together with education (taught and research programmes of study) for the benefit of the world’s railways. We actively present innovation support and assist industry to design test and commission cutting-edge technologies, whilst promoting the systems engineering culture to assure safe, reliable and punctual railway.

Contact us at railway@contacts.bham.ac.uk, follow us at @bcrre and on LinkedIn at Linkedin.com/bcrre to find out more.

You can contact Reza directly at M.R.Zolfaghari@bham.ac.uk