Joe Preece, a PhD Researcher at the University of Birmingham, describes how blockchain could make rail supply chains more transparent, thereby enhancing trust in suppliers, and doing this in a cost-effective way.

What is a supply chain?

A supply chain is the process through which materials and components travel, from production through to sale. It is a logistical network between manufacturers, which determines how a specific product reaches its end user.

For example, a fictional British-based company called Alphatech wishes to produce a new class of electric-multiple-unit (EMU) for use on British and European railways. The EMU itself is constructed by Alphatech alone. Yet the multitude of components that form the train – from the upholstery on the seats, to the wheels and bogies – are procured from different companies around the world. Each of these companies in turn resources sub-components, such as the cotton for the upholstery or the metal for the wheelset, forming complex chains between numerous stakeholders.

These chains are notoriously challenging to manage. It is difficult to share the supply chain data and guarantee the integrity with all interested parties without using a centralised and trusted intermediary. These intermediaries specialise in tracking assets across the network and sharing the information with the stakeholders. Using an intermediary guarantees that the data has not been manipulated or tampered with, but it is time-consuming and costly. Numerous companies specialise in this, requiring all stakeholders in the chain to use the same company, or face issues of chain transfer between intermediaries.

Is there a way to bypass the intermediaries? Could it be possible for supply chain stakeholders to communicate directly, whilst maintaining trust and security? Could the mechanics of blockchain technology benefit supply chains?

How does a supply Blockchain work?

To get an idea of how a blockchain might support a supply chain, consider again Alphatech, particularly the supply chain of the train seats.

Each seat is made of several materials. Firstly, the frame: a steel base to anchor the seat to the train, and a seat-shaped plastic cover. Alphatech makes the base and the cover, but procures the materials from two companies. Secondly, the arm-rest, purchased as a pre-constructed unit from yet another company. Lastly, the furnishing: foam that fits to the cover, upholstered with a mixed-material cover. Once again, the foam and the upholstery are procured from separate companies.

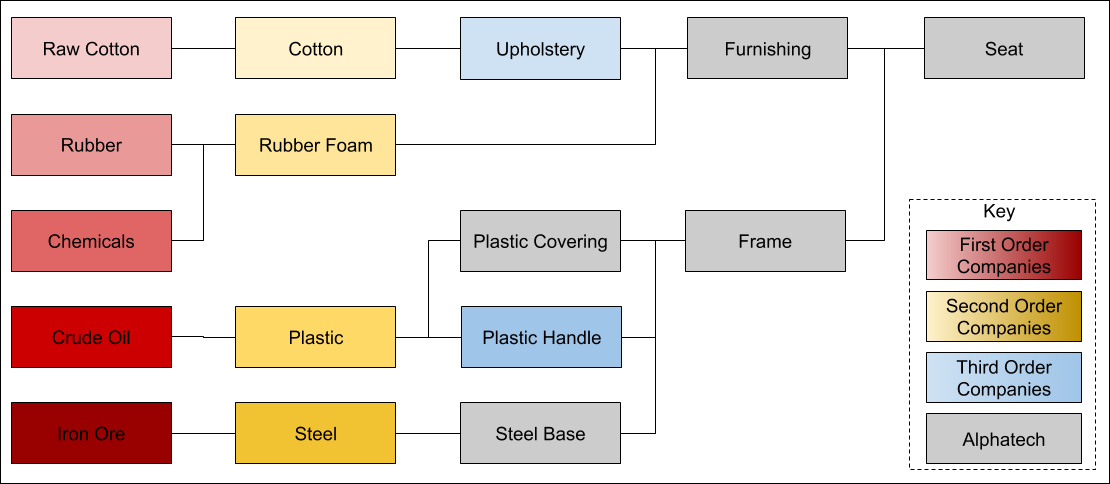

We begin to see that even for something as simple as a seat, the chain is already complex: Alphatech procures its materials from five separate companies. Each individual material will have its own procurement chains: oil refineries for the crude oil used to make the plastics, quarries for the metal ore used to make the frame, and plantations for the cotton used in the cover (see figure 1 below).

Figure 1: A supply chain network for a train seat. Materials are described by text, different companies by colour.

How are the journeys of the items tracked? Traditionally, supply chain networks use a centralised intermediary which tracks each leg of the journey. Stakeholders are responsible for notifying the intermediary about the state of the product. If they wish to trace the journey, they will need to buy the data from the intermediary. These data will seldom become available in real-time, or be fully consistent with one another, as the stakeholders must each send updates from the intermediary’s server.

Blockchain offers a potential alternative. Each product is ‘tokenised’ (i.e. represented as a digital counterpart for use on the blockchain) and transferred between stakeholders via blockchain transactions. Transactions can combine tokens representing different materials, illustrating the integration of the materials. For example, the rubber and chemicals in figure 1 combine to make rubber foam. The organisation which makes this will send a transaction with both the rubber and chemicals tokens to Alphatech which manufactures the furnishings. This transaction will also include specific details of how these materials were combined, improving the transparency of the process.

The blockchain mirrors the real process. As the materials are passed from stakeholder to stakeholder, so too are the tokens. Transparent by nature, the blockchain allows users to determine the current owner pertaining to that item at any given time, without the need for an intermediary.

Where does Blockchain add value?

There are three key advantages to using a blockchain in the supply chain: provenance, trust, and cost-effectiveness.

Provenance concerns the ability to make the supply chain data transparent. Companies and consumers can easily trace the journey of a product through the supply chain. So Alphatech could ensure that its cotton is from a fair-trade plantation, and its upholstery meets the safety standards. These transactions will indicate all the owners of all materials and components used in the upholstery, and will declare the safety information as part of these transactions.

Trust is closely related to provenance. Once the item’s journey has been traced to a stakeholder, the user can verify the validity of each component’s journey and history from the blockchain platform. There is no need to use an intermediary as the mathematics of the blockchain provide the trust.

This combination makes blockchain technology cost-effective. It removes the need for expensive intermediaries to process and transact data between companies.

Are there any drawbacks?

As with any approach, blockchain technology is not perfect. There can be technical issues. Yet it is being constantly improved. Researchers are currently looking at improving the speed of blockchains, and the interoperability of multiple chains.

How can it help the rail industry?

Blockchain is transparent, creating trust between stakeholders. The ownership and history of assets is entirely traceable. Companies purchasing used items can verify the history of all components, helping inform their decision.

Train manufacturers’ asset owners can verify the history of all parts, and provide customers with verifiable proof that their goods are made with materials of the specified quality . It allows companies to be more open with one another.

In the future, blockchain may help automate our supply chains. Supply chain data could be combined with safety data. If a sensor detects that a component needs to be replaced, it could invoke a smart contract in the supply chain blockchain, that automatically orders a brand new part, without the need for human interaction. This would save both time and money.

Conclusion

Blockchain technology has the potential to help resolve existing problems in supply chains. The technology is still new, and requires intense scrutiny before deployment on a large scale. Nonetheless, it offers a way of cutting costs whilst retaining trust between participating parties, and allows transparency across the entire blockchain, from the crude materials to the customer

Great article. As an investor and believer in the space, I believe the future of blockchain is now cemented and we can use it to build trust and transparency, particularly in the construction and business spheres. It cuts out the middle man and reduces costs throughout the system. I assume you are working on this personally within a particular field and I wish you all the best.