By An Tong, Chemical Engineering

College of Engineering and Physical Sciences, University of Birmingham

Like many other STEM disciplines, lab work tends to take up quite an important part of my course. Lab work allows us to put the theoretical concepts taught in lectures into practical use, whilst also improving our understanding of certain topics at the same time. For Chemical Engineering students, it is mainly based in the computer cluster and wet lab of the Collaborative Teaching Laboratory (CTL) main building, as well as the Dearden Laboratory in the Chemical Engineering building.

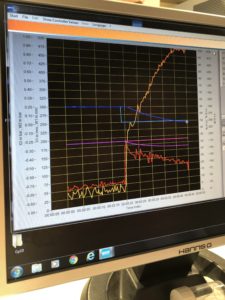

During my studies, we are expected to develop IT skills by learning how to use software such as Matlab, Simulink, AutoCAD and SimSci Pro/II. We have a three-hour tutorial in the computer cluster every week, where there are lecturers and several teaching assistants to guide us through the problem questions. Since numerical manipulation tends to be quite intensive in Chemical Engineering, Matlab can come in handy when solving high order differential equations or performing calculations over large data sets.

In order to ensure safe operation in an industrial plant, it is also essential to learn how to develop simulation models of unit operations and test their responses during the initial design stage. Other than that, we develop piping and instrumentation diagrams via AutoCAD to be presented along with our lab report. All in all, the sessions spent in the computer laboratory has equipped me with useful skills that have made my life much easier when approaching complex Chemical Engineering problems.

Experiments are usually carried out in the wet laboratory, which consists of a range of lab equipment including pumps, heat exchangers and stirred vessels. During my second year of study, the timetable was scheduled such that every Friday was dedicated only for experimental activities. Through the experiments, we were able to gain some hands-on experience on how to use the instruments and make observations via sight, sound and touch. This can be vital when it comes to design projects because we need to choose the equipment that is ideal for a region of speciality.

For instance, one of my lab reports was to carry out experiments on different types of heat exchangers (shell-and-tube, plate and tubular) and analyze their performance on heat transfer. Although they may have the same general function, it was found that the different geometries can have a huge impact on their effectiveness, and thereby affecting their industrial applications.

During these unprecedented times, it remains unsure whether students are allowed to return to the university campus for the upcoming term. It may seem a bit daunting as we are unable to use these facilities for lab work if online teaching continues. Nevertheless, all we can do now is to remain hopeful and things will go back to normal at the right timing.