In this case study we talk to Emily Allman, MEng Chemical Engineering undergraduate student, who looked into the efficiency of Resonant Acoustic Mixers (RAM) using BlueBEAR, for her final-year research project. Emily presented her paper at the recent BEAR PGR Conference 2025.

I am a final-year MEng Chemical Engineering student at the University of Birmingham. For my final year project, I explored the impact of particle-particle properties on mixing efficiency in Resonant Acoustic Mixers (RAM) using BlueBEAR. My research also aimed to resolve discrepancies in the literature regarding the effect of these properties on mixing efficiency.

What is RAM, and why is it important?

RAM is a non-contact mixing technology used in industries such as pharmaceuticals and energetics. Unlike traditional mixers that rely on blades or paddles, RAM uses vibrations to mix materials. This method is highly efficient and cost-effective, which has led to its increasing adoption in various industries.

What was the focus of this research?

During the mixing of granular materials/powders, particles interact with each other (particle-particle interactions) or with the wall of the vessel (particle-wall interactions). Each of these interactions is influenced by various coefficients, such as friction values and restitution (how elastic the collisions are). My research aimed to investigate the impact of particle-particle properties, notably friction (sliding and rolling), restitution, and fill height, on mixing efficiency.

What did the research conclude?

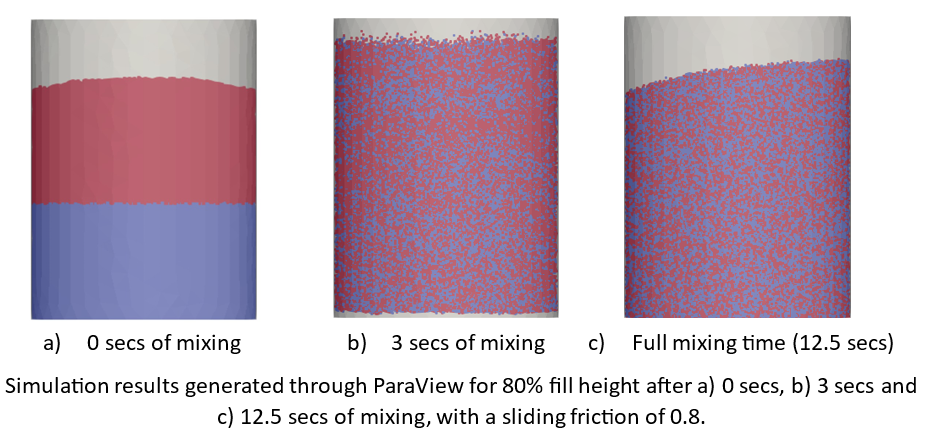

BlueBEAR allowed me to run simulations using the Discrete Element Method (DEM), a physics-based modelling system. The output files from BlueBEAR enabled me to visualise the effects of these parameters on mixing. For instance, at an 80% fill height, the following visualisation was generated:

The simulations concluded that among the properties investigated, fill height is the predominant influence on mixing performance, with the optimal fill height being around 80%, reflecting the recommended fill heights from RAM manufacturers. Furthermore, the simulations deemed that for optimal mixing, a balance is required between the free movement of particles (from low fill height and low particle-particle friction values) and resistive effects, which generate localised mixing (from high fill height and high particle-particle friction values). Additionally, particle restitution was observed to have the greatest impact at the beginning of mixing, with optimal mixing occurring at mid-range values of the coefficient.

We were so pleased to hear of how Emily was able to make use of what is on offer from Advanced Research Computing, particularly to hear of how they have made use of the BEAR HPC – if you have any examples of how it has helped your research then do get in contact with us at bearinfo@contacts.bham.ac.uk.

We are always looking for good examples of use of High Performance Computing to nominate for HPC Wire Awards – see our recent winner for more details.