In this case study, we hear from Andrew Thomas (Birmingham Medical School), a Consultant Orthopaedic Surgeon at the Royal Orthopaedic Hospital NHS Foundation Trust, who has been utilising BlueBEAR to produce a new Computational Fluid Dynamics (CFD) model of the type of operating theatre used for joint replacement surgery. The research by the team was recognised in 2021 by an HPCWire Readers Award for the best use of High-Performance Computing in life sciences, beating off prestigious competition from around the world.

The work is part of a comprehensive approach to the problem of deep infection in joint replacement surgery and the CFD model has recently been published in the high-ranking engineering journal “Building and Environment” https://doi.org/10.1016/j.buildenv.2024.111444

An informal group of researchers, led by orthopaedic surgeon Andrew Thomas and Professor Mark Simmons (right) from Chemical Engineering has made good use of the BlueBEAR computing cluster and produced a new Computational Fluid Dynamics (CFD) model of the type of operating theatre used for joint replacement surgery.

The work started with Andrew Thomas (left) collaborating with Dr Glenn Sherwood at Cranfield University to use laser imaging techniques to view the airflow patterns in an operating theatre. The work was taken further in Birmingham with Professor Mark Simmons and lecturer Dr Federico Alberini and comprehensive data on airflow velocities was obtained using an ultrasound-based anemometer.

Working with Dr Alessio Alexiadis in chemical engineering, Dr Carlos Duque-Daza, visiting

Marie Curie fellow from The National University of Columbia, Bogotá, started to develop a

CFD model based on the anemometer data. Carlos worked with his own students, Jairo Murillo Rincón and Andrés S. Espinosa-Moreno, who were sitting out the Covid pandemic in Bogotá.

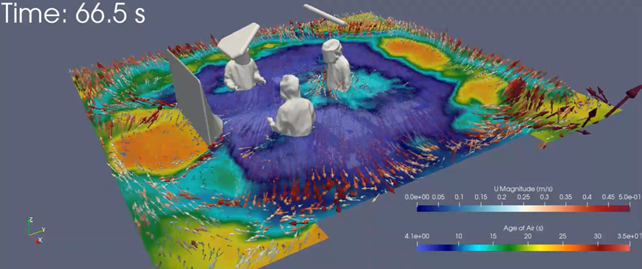

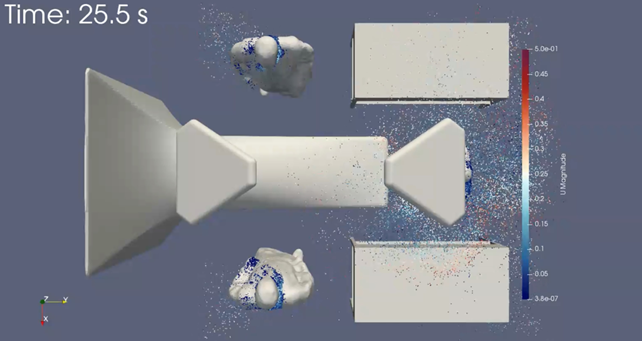

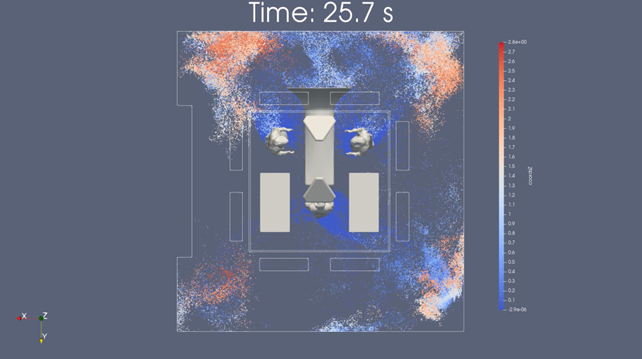

The students in Columbia were given access to the BlueBEAR cluster and Andrew Thomas and Federico Alberini made additional measurements of the operating theatre and created 3D models of the staff and equipment. The Royal Orthopaedic Hospital commissioned a comprehensive measurement of the input airflow into the operating theatre and an high resolution infra-red camera was used to obtain millions of temperature measurements, all of which was incorporated into the CFD model.

The sheer power available in the BlueBEAR system enabled the researchers to run repeated parallel CFD simulations using OpenFOAM

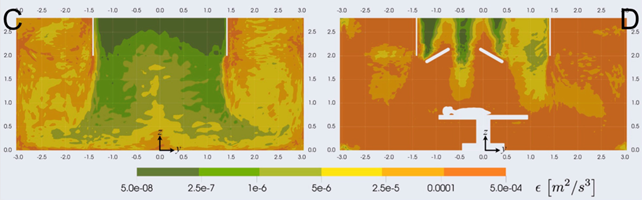

The model rapidly expanded to contain 29 million elements, with high levels of detail around the different structures in the theatre. The sheer power available in the BlueBEAR system enabled the researchers to run repeated parallel CFD simulations using OpenFOAM, which were then correlated with the anemometer measurements to check the validity of the model.

Since the team first started working together Dr Alberini has been promoted to Associate Professor of Chemical Engineering at the University of Bologna and student Jairo MurilloRincón has joined him to undertake a PhD. Student Andrés S. Espinosa-Moreno is now also undertaking a PhD at the Basque Centre for Mathematics in Bilbao.

The work of the team was recognised in 2021 by an HPCWire Readers Award for the best use of High-Performance Computing in life sciences, beating off prestigious competition from around the world.

The CFD model has revealed new insights into the effects of different types of clothing and the organisation of the lights and anaesthetic screens in ultra clean theatres. The findings have been widely presented to meetings such as the British Hip Society and the British Orthopaedic Association as well as instructional courses for Infection Prevention and Control (IPC) professionals, operating theatre staff, ventilation engineers and other professionals. Future publications will include an upcoming review of the effects of surface temperatures on airflow patterns, the effects of instrument trolly sizes and the optimization of theatre configurations

We were so pleased to hear of how Andrew and Mark were able to make use of what is on offer from Advanced Research Computing, particularly to hear of how they have made use of BlueBEAR HPC – if you have any examples of how it has helped your research then do get in contact with us at bearinfo@contacts.bham.ac.uk.

We are always looking for good examples of use of High Performance Computing, like this one, to nominate for HPC Wire Awards – see our recent winners for more details.