In this case study we hear from Khizra Abdul Wadood, a PhD student in Chemical Engineering, who has been harnessing BlueBEAR to investigate advanced powder dissolution dynamics.

From pharmaceuticals and chemical processing to fast moving goods, oral care and personal hygiene, powders are the building blocks of everything from fairly basic suspensions to the more complex slurries. Despite their ubiquity, mastering the dynamics of how these powders mix with solvents is notoriously challenging. The erratic behaviour of these tiny particles makes them fascinating yet difficult to predict. So, what makes this important, and how are we approaching these challenges?

Consider when you’re mixing cornflour to thicken soup or adding protein powder to a shake and clumps form, stubbornly refusing to dissolve. This is precisely the type of challenge my project addresses. Conventional methods for handling powders are fraught with inefficiencies, largely because they rely too much on inconsistent empirical data. This inconsistency is exactly why we’re turning to computational simulations, which become indispensable in situations where experimenting with rare and costly materials is impractical.

At the University of Birmingham, the BlueBEAR high-performance computing (HPC) cluster has become essential in our search for deeper insights. By leveraging BlueBEAR’s capability of running various numerical models and simulations, researchers can simulate the mixing of powders with fluids, combining the complexities of fluid dynamics and discrete particle simulations—an endeavour that often feels like wrestling with a two-headed beast.

BlueBEAR high-performance computing (HPC) cluster has become essential in our search for deeper insights

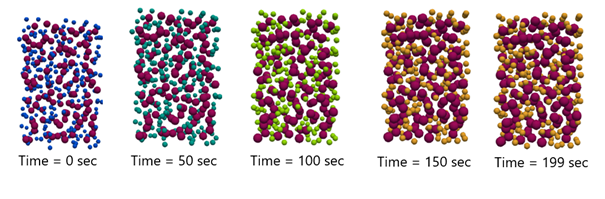

Our research employs a blend of techniques to model these interactions. Using LIGGGHTS for Discrete Element Method (DEM) modelling, we simulate the swelling behaviours of powders (Figure 1). We are pushing the envelope further by incorporating water and enabling two-way interactions between particles and fluids. This effort aims to push the boundaries of our current capabilities, facilitating a dynamic exchange that reveals insights previously beyond our reach. Thanks to BlueBEAR’s support for LIGGGHTS, OpenFOAM, Lethe, and DualSPHysics, we can undertake simulations that require immense computational power and generate vast amounts of data.

Why are we investing so much effort? The costs—both material and financial—of not using simulation are simply too high, especially when experimenting with new formulations involving rare materials. Simulation offers a viable alternative, enabling us to refine our processes virtually before we measure a single gram in the real world.

The implications of improving our simulation techniques are significant. As we enhance our methods, we’re contributing to a move from batch-based processes to continuous ones, particularly in the pharmaceutical industry. This isn’t merely a technical upgrade; it’s a potential revolution in how medicines are produced, boosting efficiency and reducing waste.

This isn’t merely a technical upgrade; it’s a potential revolution in how medicines are produced, boosting efficiency and reducing waste

Consider a basic simulation: particles falling into a glass cylinder. Even this simple model can provide insights into the cohesiveness of particles and their behaviour, which are crucial for manufacturing products from pills to toothpaste. By tweaking variables such as particle friction and elasticity, we’re able to forecast how microscopic changes can impact the larger processes at work.

Here’s where BlueBEAR truly proves its worth. By running thousands of these simulations, with variations in particle properties, we can create a detailed model that links these tiny details to the bigger picture we observe. This isn’t just theoretical; it has practical applications in designing more reliable and efficient processes and equipment, reducing the likelihood of roadblocks and inconsistencies in production.

BlueBEAR is more than a tool

As we venture further into this intricate field, the significance of BlueBEAR has proven absolutely essential. BlueBEAR is more than a tool; it’s not just about easing our workload; it’s about making industries more sustainable, efficient, and innovative, it’s a cornerstone of modern powder research, pushing us to expand the boundaries of one of the most challenging areas in science and engineering today. With each simulation, we’re not just solving problems—we’re simulating solutions.

We were so pleased to hear of how Khizra was able to make use of what is on offer from Advanced Research Computing, particularly to hear of how he has made use of BlueBEAR HPC and its many cores – if you have any examples of how it has helped your research then do get in contact with us at bearinfo@contacts.bham.ac.uk. We are always looking for good examples of use of High Performance Computing to nominate for HPC Wire Awards – see our recent winners for more details.