With its origins traceable to the Japanese Toyota Production System and the publication of one of the best-selling books amongst both academics and practitioners, ‘The Machine that Changed the World’, the concept of lean production has received substantial attention and has become well embedded within automotive studies in Operations Management (OM) and Supply Chain Management (SCM). Over the last 30 years, although it has been continuously developed and refined, the philosophy behind lean remains simple and clear. The underlying principle, that all waste be eliminated, has led to the assertion that the lean concept is applicable to any organisation or economic system. However, in an age of modern technology where the push of a button can alter production systems dramatically, it is indisputable that the dynamics of the global marketplace are not the same today as they were in the past. More specifically, the global automotive industry has been facing six challenges: (1) A general shortage of qualified engineers/operators; (2) Extreme fluctuations in terms of product mix and production volume etc.; (3) Safety precautions; (4) Energy efficient production techniques; (5) Reduction of production costs; and (6) The availability of products in time. Issues (2) and (6) suggest that within the current automotive business environment, in order for firms to survive and compete, the capability to responding quickly and effectively to customer needs are becoming very important.

With its origins traceable to the Japanese Toyota Production System and the publication of one of the best-selling books amongst both academics and practitioners, ‘The Machine that Changed the World’, the concept of lean production has received substantial attention and has become well embedded within automotive studies in Operations Management (OM) and Supply Chain Management (SCM). Over the last 30 years, although it has been continuously developed and refined, the philosophy behind lean remains simple and clear. The underlying principle, that all waste be eliminated, has led to the assertion that the lean concept is applicable to any organisation or economic system. However, in an age of modern technology where the push of a button can alter production systems dramatically, it is indisputable that the dynamics of the global marketplace are not the same today as they were in the past. More specifically, the global automotive industry has been facing six challenges: (1) A general shortage of qualified engineers/operators; (2) Extreme fluctuations in terms of product mix and production volume etc.; (3) Safety precautions; (4) Energy efficient production techniques; (5) Reduction of production costs; and (6) The availability of products in time. Issues (2) and (6) suggest that within the current automotive business environment, in order for firms to survive and compete, the capability to responding quickly and effectively to customer needs are becoming very important.

“Received wisdom” within the SCM discipline suggests that automotive supply chains are predominantly lean in nature. That same “wisdom” also suggests that where lean and agile firms coexist in a supply chain, the agile firms will be located downstream, close to the customer, while the lean firms will be located further upstream. With this in mind, the purpose of our study was to robustly establish whether firms are implementing lean or agile production in the automotive supply chain and, by drawing on Contingency Theory as our theoretical lens, independently determine whether lean and agile firms can be distinguished based upon contextual factors. Although there has been extensive research concerning the philosophy of lean production within the automotive industry, there is a scarcity in studies focussing on the automotive industry in line with contextual factors, especially concerning the role of supply chain positional tier.

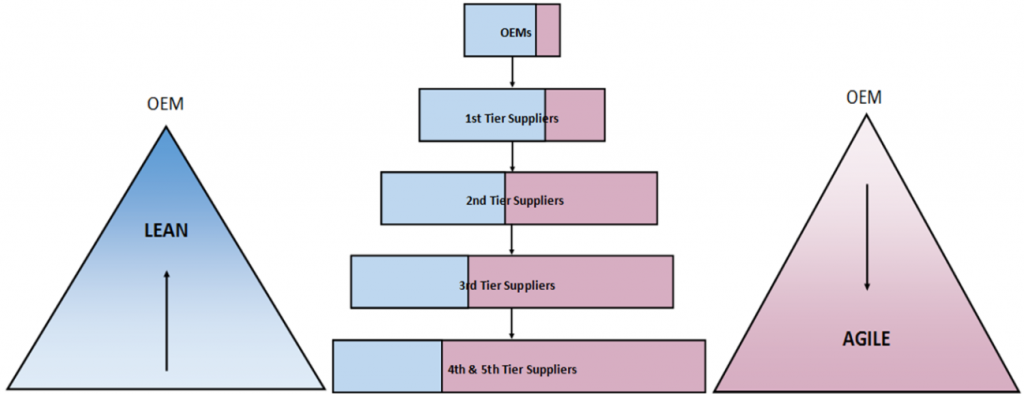

Findings from 140 firms operating in the West Midlands automotive industry suggested that lean and agile firms do co-exist in the automotive supply chain. More specifically, we found lean firms to be significantly more likely to be positioned at higher tiers (OEMs, First-Tier, Second-Tier) of the automotive supply chain, while agile firms were significantly more likely to be positioned at lower tiers (Third-Tier, Fourth & Fifth-Tier) of the automotive supply chain. We visualise our findings in the form of the LAASC (Lean Agile Automotive Supply Chain) Model, see Figure 1.

Figure 1: The LAASC Model – Source: Qamar & Hall (2018)

Figure 1: The LAASC Model – Source: Qamar & Hall (2018)

Not only is the importance of Contingency Theory theoretically approved, but “received wisdom” within SCM is also contested. Extant literature propagates that the automotive supply chain is comprised of organisations that predominantly adopt lean production methods, and that in supply chains comprised of both lean and agile organisations, the firms closer to the customer will adopt more flexible (agile) practices, while those that operate upstream will adopt more efficient (lean) practices. The findings from this study have implications for theory and practice, as lean and agile firms can be found in the automotive supply chain without any relationship to the value-adding process. To speculate as to why the findings contest existing views, Resource Dependence Theory and, more specifically, a power perspective, was invoked. We believe we provide readers with a new way of thinking concerning complicated supply chains and urge that the discipline of SCM adopts a “fourth” supply chain model, depicting a new lean and agile supply chain configuration.

This blog was written by Dr Amir Qamar, Research Associate, City-REDI, University of Birmingham.

This blog reports on the findings of his recent publication:

Free online access to 50 first views can be found by clicking this eprint link

Disclaimer:

The views expressed in this analysis post are those of the authors and not necessarily those of City-REDI or the University of Birmingham

To sign up for our blog mailing list, please click here.

Image from Pixabay / markusthomasde CCO