The majority of studies which have investigated lean and agile production have explored each of these production concepts in silos, which is a growing trend in the recent literature. Given that a number of studies assert that flexibility is an essential factor for differentiating lean and agile production there is an important need to explore both of these production concepts simultaneously. Furthermore, there is limited research on flexibility, especially Supply Chain Flexibility (SCF), which is as a gap identified in the literature.

Flexibility concerns the ability of organisations to adjust or change their operation in some way. These changes may involve the following: what the operation does, how long it takes for the completion of a task and when the operation occurs. Traditionally, flexibility can be categorised into two groups: Internal Flexibility (IF) and External Flexibility (EF). However, authors have identified the importance of a third dimension, namely SCF. IF refers to the flexibility that can occur within systems, EF refers to the flexibility that can be observed by external customers and SCF refers to the ability of a firm to reconfigure their respective supply chains.

Although lean originated from the automotive industry, Automotive Supply Chains (ASCs) also require high levels of flexibility. For instance, one in six firms decided to bring manufacturing back to the UK between 2011 and 2014, with flexibility being a key driving force, which is why we broadened our attention to agile production. With this in mind, the aims of our study was to: (1) explore the critical differences between levels of flexibility which are derived from lean and agile production methods; and (2) investigate where lean, agile and high levels of flexibility are located within the ASC.

As flexibility is in its infancy stage of theoretical development we make an empirical contribution by developing a taxonomy that distinguishes each production concept. Theoretically, our findings support the notion of trade-offs and Skinner’s (1969) assertion that manufacturing strategies compete on different performance objectives. This is framed by an approach taken from the strategy literature on business models and dynamic capabilities, which links the positioning of supply firms within the ASC to specific tools, practices, routines and concepts they have evolved to underpin different kinds of competitive advantage.

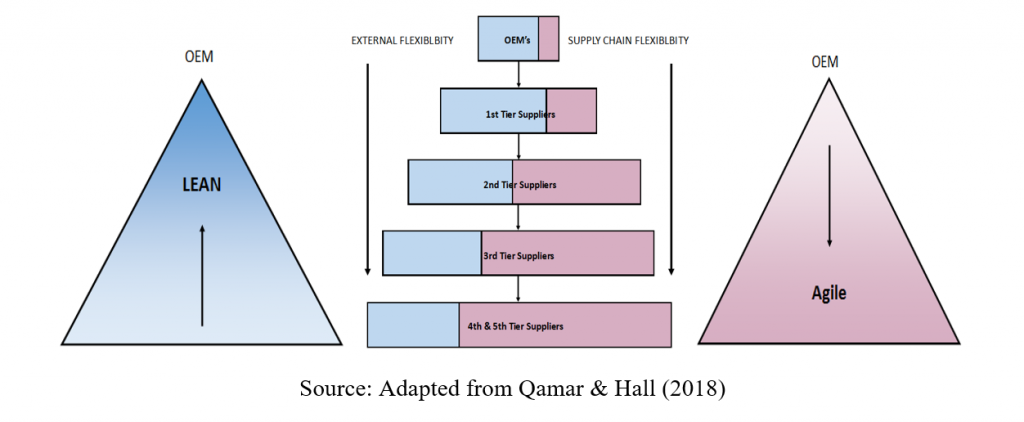

Figure 1 – LAASC (Lean Agile Automotive Supply Chain) Model

Perhaps most importantly, we build on Qamar & Hall’s (2018) Lean Agile Automotive Supply Chain (LAASC) Model, by illustrating where flexibility levels are located within ASCs. Flexibility findings in conjunction with the LAASC model refutes extant supply chain literature as ASCs were not identified as solely being lean, as both lean and agile firms were found to be operating in the ASC. More specifically, high levels of flexibility (agile) and low levels of flexibility (lean) were found upstream and downstream of the ASC respectively. As this finding directly contests ‘received wisdom’ regarding where lean and organisations are located within an ‘agile’ supply chain (SC), we provide insights from the business models, dynamic capabilities and power literature to explain our findings.

This Blog reports on the recent publication:

Qamar, A., Hall, M. A., & Collinson, S. (2018). Lean versus agile production: flexibility trade-offs within the automotive supply chain. International Journal of Production Research, 1-20.

Free online access to 50 first views can be found by clicking this eprint link.

References:

Qamar, A., & Hall, M. (2018). Can Lean and Agile organisations within the UK automotive supply chain be distinguished based upon contextual factors?. Supply Chain Management: An International Journal.

This blog was written by Dr Amir Qamar, Research Associate, City-REDI, University of Birmingham.

Disclaimer:

The views expressed in this analysis post are those of the authors and not necessarily those of City-REDI or the University of Birmingham.

To sign up for our blog mailing list, please click here.